After the closure of mining operations in 1933, the plant was abandoned and deserted for a number of years. Towards the end of the 1940s, the state, through the then REF – the National Committee for Economic Defense Preparedness – began to take an interest in the mine. Sweden’s Geological Survey carried out several nationwide investigations and inventories with the aim of finding suitable disused mines that could be used for storing oil in various forms. So-called protected storage of propellant in rock rooms usually consisted of independent steel tanks or steel-concrete tanks inside the rock rooms. The products were completely separated from the groundwater in the surrounding rock. Now the needs increased and the storage capacity had to be expanded. Storing oil on a bed of water in unlined rock chambers was a new and economically advantageous method that was beginning to be widely accepted. The societal benefit was judged to be more important than the risks in the form of impact on groundwater and pollution of the surroundings that the method entailed.

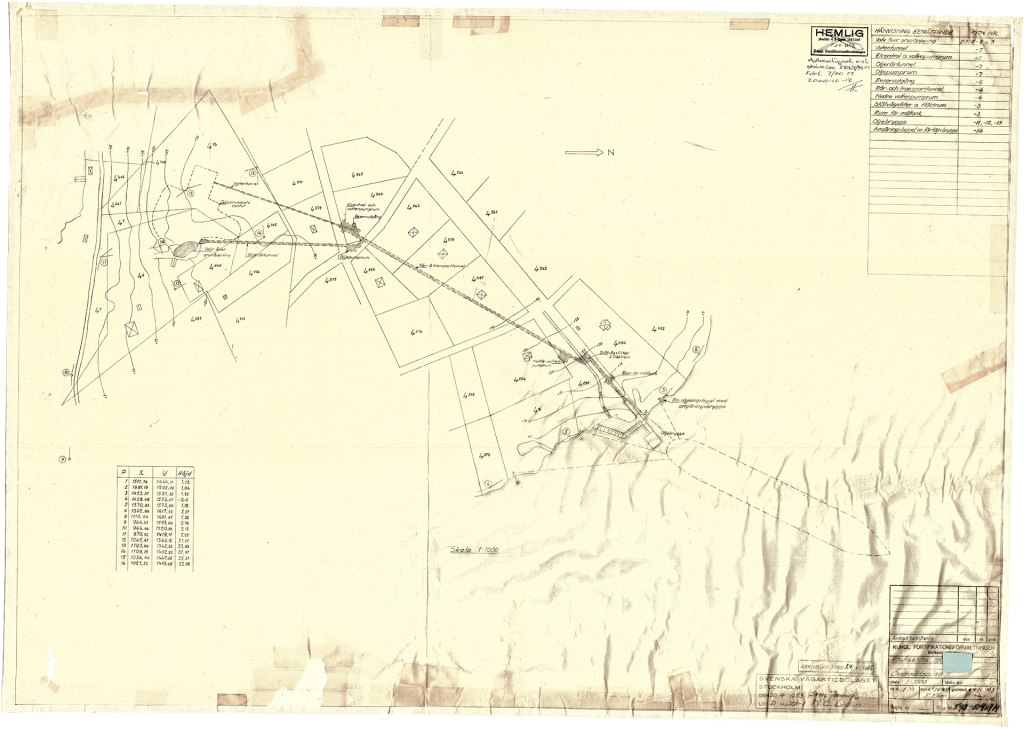

Eventually, the developed rock blasting technique could be used to create new large rock chambers, but for now they had to be content with using existing mines. In a memo from 1948, the quartz and feldspar mines in the Stockholm archipelago were reported with regard to internal space and the size of the day opening. Ytterby mine was stated to have a dimension of approximately 57,000 m3. The mine was judged to be suitable as a storage facility. The risk of contaminated groundwater was said to be low because the rock was very dense and mining had been concentrated with only a few localities. The mine was also large enough and easily accessible for ocean-going ships. The air force’s need for fuel increased and Ytterby became a new fuel facility for the storage of aviation fuel – MC 77. In the early 1950s the state bought the area and in 1953 the mine was rebuilt by the then Vattenfallstyrelsen. Between the mine and the new quay that was built on the south-eastern part of Resarö, 500-600 meters of tunnels were blasted for the loading and unloading of oil and bed water respectively. The mine opening was sealed with a concrete vault that was covered with approximately 15 meters of explosives and over this a concrete blast jacket was erected. Rock clearing was carried out, pipes and pumps were installed.

The oil products were stored in the unlined rock room below the natural groundwater level. Therefore, groundwater constantly flowed into the rock space and prevented the oil from spreading in the rock. The liquid in the rock chamber also exerted a back pressure that reduced the inflow of groundwater. Despite the pressure from the surrounding groundwater, small remnants of oil could find their way out in cracks. The oil was pumped into the mine from ships that docked at the wharf. The principle of the storage is that oil is lighter than water and thus the oil could float on top of a water bed. As this water bed was mobile, it meant that the mine was always filled regardless of how much oil was stored. The level of the water, and thereby the oil, was regulated by pumping water in and out. Water was pumped out when the corresponding amount of oil was pumped in and vice versa. The oil reservoir itself consisted of the mine room between the height +8 and -110 meters. The water bed filled the lower part of the mine, below -110 meters. The outlet for oil opened into the mine at the +2 meter level, while the water tunnel was deep and opened into the mine at the -107.5 meter level. The lowest level for the interface between bed water and oil was -100 meters. The level of the oil was between +2 and +8 meters, normally +4 meters.

The long-term storage of jet fuel continued until 1978 when it was discovered that hydrogen sulphide had formed in the product. The sulfur had been developed by the micro-organisms that existed in the contact area between fuel and water. The result was several total breakdowns when the fuel pumps for some aircraft engines were affected by sulfur attack on silver-plated surfaces. The facility was emptied of its contents and 50,000 m3 of jet fuel was re-refined. During the years 1980-1983, the facility was rented by Svenska Petroleum AB for the storage of diesel. In 1985 it was filled with diesel for use by the navy and in 1995 the product was sold and the mine emptied of its contents. Since then, the facility has been empty. During the entire time that the oil storage was in operation, no environmental disturbances have been reported.

The storage facility has been managed by

- Vattenfallsstyrelsen (1953-1975)

- MFÖ – Östra militärområdets materielförvaltning (1975-1988)

- MFM – Mellersta militärområdets materielförvaltning (1988-1993)

- MKO – Ostkustens marinkommando (1993-1999)

- The Fortification Agency (1999-).

It takes a long time to decommission a storage facility for petroleum products in a way that does not risk damaging the environment. Work on the decommissioning started around 1997 with the goal of eventually being able to fill the mine with water. Residues of oil were removed by pumping and oil separation. In the fall of 2000, a final emptying was done when approximately 500 m3 of product was pumped out, and in 2001 an environmental impact investigation was carried out with the aim of submitting proposals for the appropriate type of post-treatment. In 2006, ventilation of the mine area began, a measure that is expected to last for a ten-year period. The clean-up process is followed up in a control program. In 2007, the County Administrative Board carried out a risk classification and the area was then classified as an object with low risk.

Text in swedish: Lena Knutson Udd & Tommy Leek 2012. English translation by unknown.